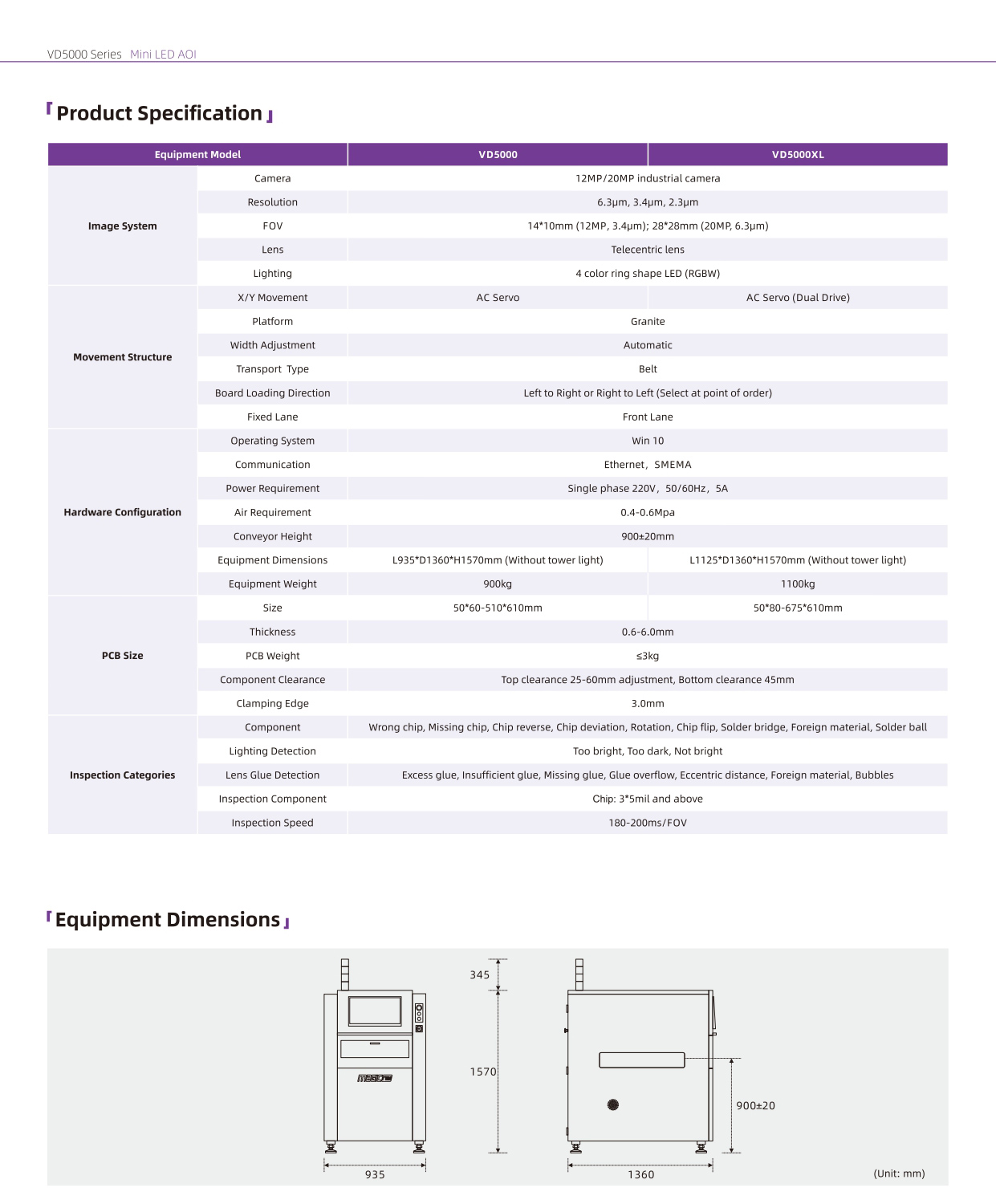

VD5000

Mini LED AOI

MagicRay Mini LED AOI一VDSOOO series, Able to provide chip appearance inspection, lighting appearance inspection solution in the field of Mini LED.

▶ Simple and Convenient Programming

▶ High Precision Positioning and Faster Calculation Speed

▶ Specialized Lighting and Algorithm for Lens Glue Detection

Function and Feature

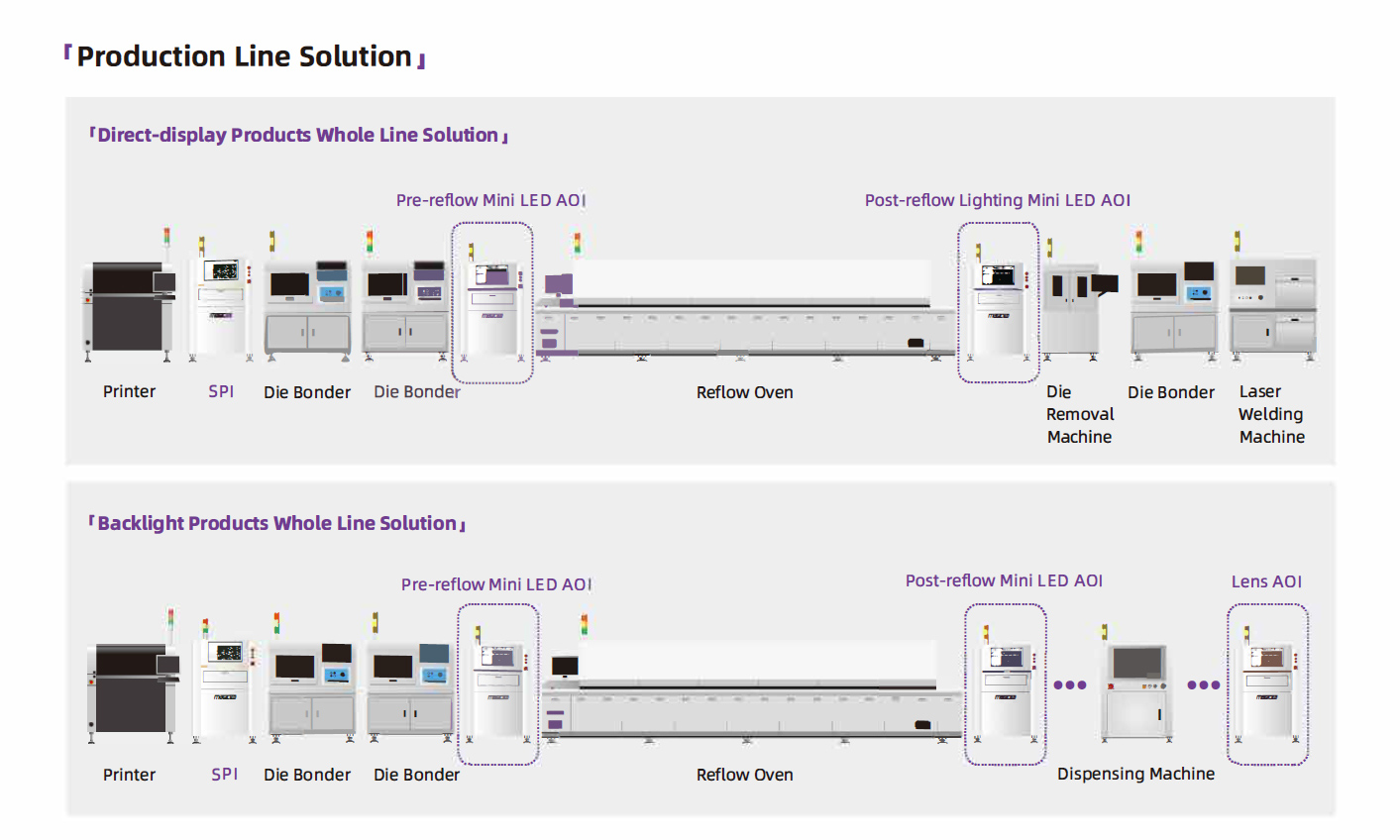

Mini LED Direct-display and Backlight Inline AOI

Suitable for the Pre-and-Post reflow appearance inspection of Mini LED directdisplay products, as well as the after-lighting detection of direct-display products.

Suitable for the Pre-and-Post reflow appearance inspection of backlight products, as well as the appearance inspection of Lens glue.

Granite platform+casting gantry to realize high reliability and stability.

Industrial camera+high resolution telecentric lens to ensure high accuracy.

Accurate positioning and detection based on image-featured algorithm with low false call rate.

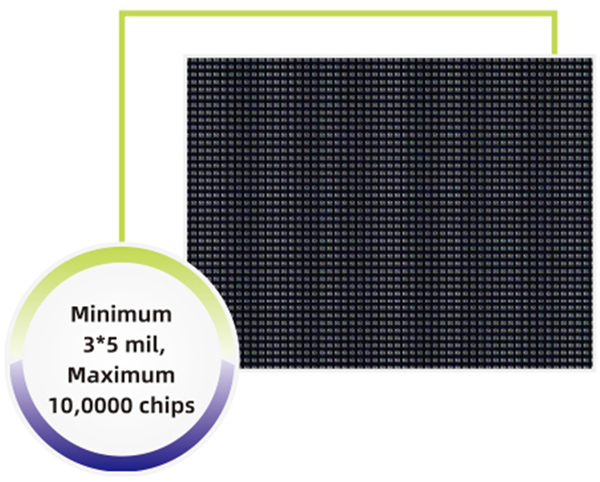

Applicable to the appearance detection of chips at minimum of 3*5mil.

Applicable to test up to 100,000 chips.

Inspection Examples

Chip Appearance Inspection

▲Missing Chip

▲Misalignment

▲Chip Flip

▲Foreign Material On The Bottom

▲Misalignment

▲Double Chip

▲Tombstone

▲Lifted

Lighting Inspection

▲OK

▲LED No Glow

▲Misalignment

▲Flip Component

▲Missing Component

▲Extra Part

▲Foreign Material

Lens Glue Appearance Inspection

▲OK

▲Excess Glue

▲Insufficient Glue

▲Skewing

▲Missing Glue

▲Bubbles

▲Odd Shape

Core Technology and Advantages

Simple and Convenient Programming

Multi-component three-point array automatic generation function, ignoring the inclination of the sample board, realizes the rapid generation of huge component test windows.

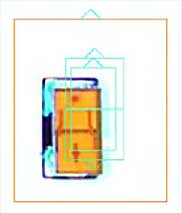

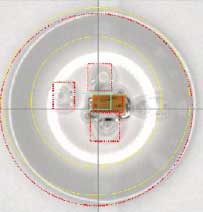

High Precision Positioning and Faster Calculation Speed

High-precision positioning and measurement can be realized by highresolution lens+component-level pad positioning+specific component positioning algorithm, and at the same time, it has faster calculation speed.

▲Before positioning

▲After positioning

Specialized Lighting and Algorithm for Lens Glue Detection

Specialized lighting to ensure a clearer view of glue contour under inspection. Combined with contour comparison and Al deep learning algorithm, our machine can effectively measure the diameter and detect defects like unshaped glue, bubble, folds etc.

▲Bubbles

▲Specialized lighting